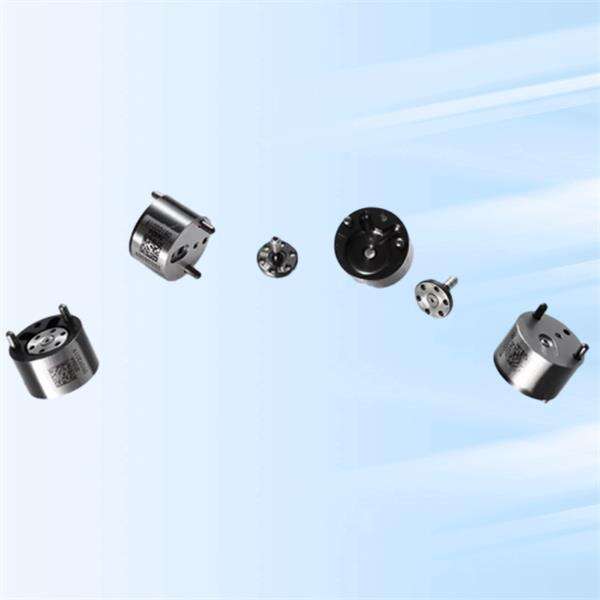

A diesel fuel injector is a combination of various components. Close up performance of air or fluid can be achieved using these parts; hence, the major purpose of these is to increase the pressure that make it go faster. It improves the functionality of the machines. Primary components of a booster valve assembly are the valve body, stem, spring, diaphragm and solenoid.

Inside the valve body, air or fluid enters and pushes on top of the diaphragm. This forces the diaphragm to expand. When the diaphragm stretches, it also stretches a spring inside. It also contains a spring which when sufficiently expanded opens the valve. That makes the air or fluid to flow through that valve at a higher pressure than it was. This procedure is an essential step as it makes the machine function more efficiently.

Caring for a common rail injector is every bit as important as its commissioning. Maintenance in the general sense typically involves inspecting and occasionally cleaning the assembly. By way of example, this ensures that all the parts function and are in good condition. Any defective or worn parts that possess damage should be replaced immediately. Replacing it on time prevents issues with pressure regulation, allowing the machine to function properly.

Booster valve assemblies have a variety of advantages for use in industrial systems. The most significant benefit for good pressure regulators is a matter of handling the air or liquid pressure and as a result, they optimize the functioning of the system. Regulated pressure may help the overall working of the machine by preventing mechanical failures or damages.

Booster valve assemblies offer both functional benefits and help in lowering costs while improving on safety in the industrial age. Breakdowns are less likely to occur in systems where pressure and flow are tightly controlled. This minimizes their requirement for costly repairs or replacements, saving money in the long-run. Finally, accurate pressure and flow assists in not injuring or damaging any matches due when the pressure or flow become unreachable.

However, like everything else, there are some common issues with these booster valve assemblies that you may need to troubleshoot. An internally damaged diaphragm is one of the most common concerns. The result is that the pressure can be lost, and consequently also greatly reduced in system performance. An undamaged diaphragm can leak, however, as a result of incorrect installation or dirt entering the valve body or diaphragm.

Derun Mechanical has a whole stack of booster valve assemblies available for many different industrial applications. We're available to help you select the proper assembly — our team has facilitators happy to assist at any time. Plus, you can get complete installation, maintenance, and repair too. They are the services that help you run your system at its peak performance.

Derun has more than 300 sets of advanced processing equipment and has introduced the latest production technology in the world, as well as advanced testing and manufacturing equipment, as well as industry introduction of research and development and manufacturing technology. Derun employs more than 360 employees comprising 10 engineers who are senior. Injector valves, fuel injection assemblies, fuel pumps, the nozzles and many more models are being developed with booster valve assembly.

Derun booster valve assembly automotive diesel engine parts manufacturer China 1000 parts 38 years expertise leader field. Derun's products distributed throughout world overall more 300 suppliers around world. In present it set up three subsidiaries China established cooperative relations more 30 countries around globe.

Derun has been accredited with ISO9001 as well as ISO/TS16949. Derun employs a broad variety of high-quality testing equipment. It also inspects each part before it booster valve assembly the factory.

Derun is committed to the growth of green companies as its main goal. The company always puts the protection of the environment in the first place in the production and research and development. Derun is committed to the booster valve assembly of diesel engines with low emissions, low noise, high performance and light pollution.

Copyright © Guangzhou Derun Mechanical & Electrical Fittings Co., Ltd All Rights Reserved - Privacy Policy