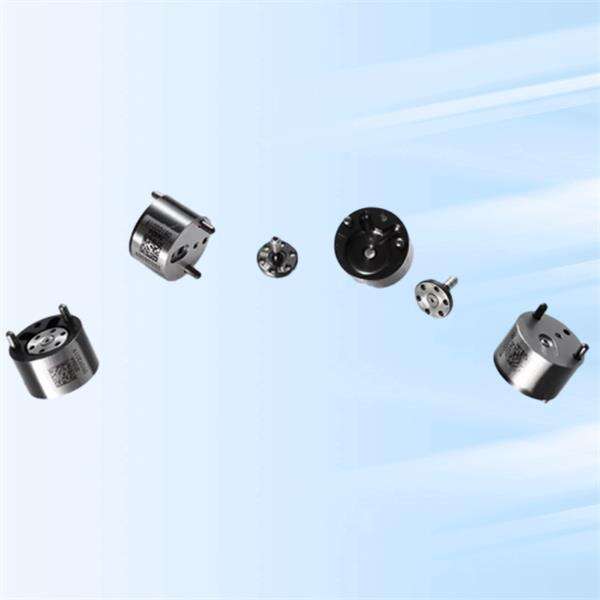

They are usually used in machines that require functioning working of the booster valve assemblies. They work as the machine's control center, keeping everything in order. For the machine to operate properly, it needs a functioning booster valve assembly.

It is not only a valve assembly but also a booster valve assembly. It (helps to) regulate(and) relieve pressure and flow of the fluid, which (allows) the machine to function properly. A machine can fail to operate properly without the boost valve assembly.

Preventative maintenance is key to ensuring a booster valve assembly is working well. Preventive maintenance through regular checks and cleaning can prevent problems from occurring. Well, by performing proper maintenance on the booster valve assembly, you can ensure that it gives you a long and smooth service life.

Once in a while booster valve assemblies can encounter issues that must be resolved. A faulty booster assembly might be at fault if a machine is not performing correctly. Typical issues include leaks, blockages, or things not functioning properly. The machine can operate normally again if the problems get identified and repaired without delay.

Booster valve assemblies fall into two main categories, manual and automatic. Manual booster valve assemblies require a person to operate for flow of fluids, while automatic booster valve assemblies spices up zelfstandige operation from the set conditions. Each has pros and cons, depending on what the machine needs.

Ensuring longevity of a booster valve assembly is easy, though. Good maintenance, proper cleaning and early repairs can prevent problems. Using the proper materials and also following the manufacturer directions for using the machine are also keys to a successful sewing experience.

Derun one largest booster valve assembly China 38 years production experience 1000 parts. Available across globe 300 customers around globe. Set up 3 subsidiaries China good relationship more 30 countries.

Derun has been certified booster valve assembly as well as ISO/TS16949. Derun's facilities include a variety of sophisticated quality testing equipment. The company strictly inspects all parts before leaving the factory to do the best job at quality control.

Derun owns more than 300 sets of modern processing equipment. It has developed world-class production technologies, advanced testing and booster valve assembly, as well as industrial introduction of research and manufacturing technologies. Derun employs more than 360 people comprising 10 senior engineers and 20 quality-control supervisors. Injector valves, fuel injectors assemblies, fuel pumps, various nozzles, and more are being developed with success.

Derun has set the booster valve assembly of creating sustainable enterprises and always considers the protection of the environment first in production and research in development. It is also a firm believer in diesel engine powered businesses that have low emissions, low noise as well as high-performance and light pollution.

Copyright © Guangzhou Derun Mechanical & Electrical Fittings Co., Ltd All Rights Reserved - Privacy Policy