The common rail system consists of three main components which work together. These components are a pump, rail and injectors under high pressure. The pump is first in the line because it is vital to push the fuel into the rail. The rail serves to store the fuel at high pressure. From there, the rail delivers the fuel to the injectors. The injectors play an essential part, as they spray the fuel into the engine at very high pressure. This generates a high-pressure spray, which causes a big bang in the engine and pushes the pistons. The pistons are these little arms that shake the pieces of the engine around to help the car move!

This allows greater power — The common rail can inject fuel multiple times per engine cycle. The fact that it can make several injections translates into a bigger bang, allowing the engine to produce that much more power to propel the vehicle.

To be fair, injector diesel common rail system is like any other machine and it needs to be treated with some respect. It's wise to know what to do too when it has occasional trouble. Follow these points to maintain your system well during the winter months:

Correct Fuel: The common rail system is compatible with the studied kind of fuel only. For this reason you need to ensure you are using the proper type of fuel. Actually, this would lead to issues and could damage the system if you are using the wrong fuel.

Troubleshoot – In case you experience any kind of issue in your common rail, it is best to visit an expert technician. They will be able to diagnose the problem and fix it so you have your engine running smoothly again.

Add a comment The history of common rail system is not so common. The answer dates back to the 1990s, when Bosch and Denso were first to market with the tech. After that, things have continued to get much higher for the technology. For instance, some newer systems may also utilize proprietary piezoelectric injectors compared to conventional solenoid injectors. This new style of injector has the advantage of providing greater control of what fuel that is injected into the engine.

The common rail system should play an even greater role in the future, as auto manufacturers strive for improved engine efficiency and reduced harmful emissions output. Some experts think that all diesel engine will be outfitted with this sophisticated technology. Research is also underway to utilize the common rail system with gasoline engines as well. That could mean the benefits of this tech will be extended to even more vehicles.

Derun is an organization certified by ISO9001 and ISO/TS16949 quality system. The company has a variety of the common rail testing equipment, and strictly inspects all parts before leaving the factory to do an excellent job of quality control.

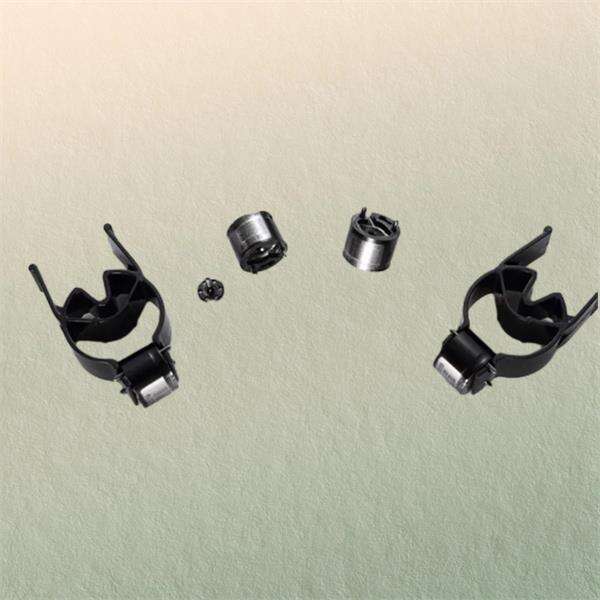

Derun has more than 300 sets of advanced processing equipment and has introduced the latest production technology in the world, as well as advanced testing and manufacturing equipment, as well as industry introduction of research and development and manufacturing technology. Derun employs more than 360 employees comprising 10 engineers who are senior. Injector valves, fuel injection assemblies, fuel pumps, the nozzles and many more models are being developed with the common rail.

Derun is one of the the common rail for automotive components manufacturers in China that has more than more than 38 years of production and more than 1,000 components. The products we sell are sold all over the world, through 300+ dealers. It has currently set up 3 subsidiaries in China and has established strong cooperating relationships with more than 30 countries around the globe.

Derun is committed to the growth of green companies as its main goal. The company always puts the protection of the environment in the first place in the production and research and development. Derun is committed to the the common rail of diesel engines with low emissions, low noise, high performance and light pollution.

Copyright © Guangzhou Derun Mechanical & Electrical Fittings Co., Ltd All Rights Reserved - Privacy Policy