It is an advanced technology that helps enhance the performance of the vehicle whilst also improving its fuel efficiency. Fires when under high pressure, which pushes fuel into the engine which, in turn, produces more power. In simple terms, this means that a vehicle equipped with this technology can accelerate more quickly while consuming less fuel at the same time. This is like super-charging your engine and at the same time, making it affordable as well as eco-friendly!

Next, there is a fuel pump. The task of the fuel pump is to draw the diesel from the tank and deliver it to a component known as the common rail. The common rail is extremely important as it works with fuel like a highway. It ensures fuel flows to every component that requires it — particularly the fuel injectors.

Last come the fuel injectors. These are the minor components that retrieve the diesel from the common rail and inject it into the engine. When the fuel enters the engine, it mixes with air to create an explosive reaction that powers the engine. All of this occurs rapidly, so the engine gets plenty of power when you step on the gas pedal.

When comparing 6.5 turbo diesel injectors with older systems, there are many advantages that make this a better system. The kilowatts produced per litre of fuel burnt is one of the major benefits. That means you can go further without needing to fill the tank as often, which is good for saving cash at the pump.

For a turbo diesel system to operate effectively, there are a number of important components. The common rail in the first part. The common rail is a long tube that all the fuel injectors are connected to. All the injectors get their fuel from this tube, similar to how a pipeline sends water to different places.

The second very important part that you may be aware of is the fuel pump. It is the one that s a diesel to the common rail at the right pressure. If the pressure is too low, the engine does not receive enough fuel. If it’s too low, it could cause problems. It is essential, therefore, that the engine is running at the right pressure.

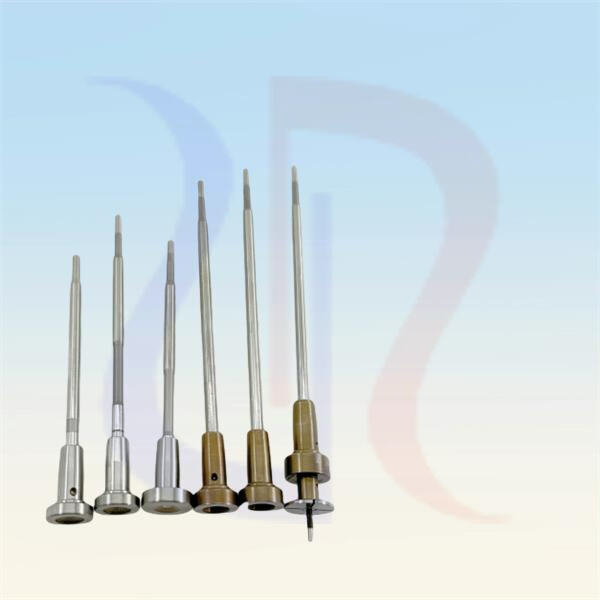

Last but not least, we have the fuel injectors. These are the components that actually spray the diesel into the engine. They must function properly to ensure that the correct amount of fuel enters the engine at the appropriate moment. The engine may run badly — or not run at all — if the fuel injectors fail to work properly.

Derun is committed to the turbo diesel common rail injection of green enterprises as its main goal. The company always puts the protection of the environment in the first place in both research and development. The company is dedicated to the power of diesel engines with low emissions, low noise, excellent performance and light pollution.

turbo diesel common rail injection owns more than 300 sets of the latest processing equipment. It has developed high-end production techniques, the most advanced testing and manufacturing equipment, as well as industrial introduction of research and manufacturing technology. It owns more than360 employees comprising 10 senior engineers, and 20 quality-control executives. They have developed and tested various models of fuel injectors. inlet valve assembly, fuel pumps, nozzles etc.

Derun turbo diesel common rail injection automotive diesel engine parts manufacturer China 1000 parts 38 years expertise leader field. Derun's products distributed throughout world overall more 300 suppliers around world. In present it set up three subsidiaries China established cooperative relations more 30 countries around globe.

Derun has been certified turbo diesel common rail injection as well as ISO/TS16949. Derun's facilities include a variety of sophisticated quality testing equipment. The company strictly inspects all parts before leaving the factory to do the best job at quality control.

Copyright © Guangzhou Derun Mechanical & Electrical Fittings Co., Ltd All Rights Reserved - Privacy Policy