أنظمة حقن الوقود هي مكونات أساسية في أي محرك سيارة. مساحيق الوقود مسؤولة عن توفير الوقود للمحرك وضمان احتراقه ليعمل المحرك بسلاسة. هناك العديد من أنواع مساحيق البنزين المختلفة، ويعتمد الأداء الكلي للمحرك على وجود نظام جيد. سنتناول في هذا النص التعمق في حاقن وقود الديزل ، ومناقشة السبب في كونها ضرورية للغاية لصناعة السيارات.

هناك عدة مكونات لنظام حقن البنزين تعمل معًا لتوفير الوقود للمحرك. وتتضمن هذه المكونات أجزاء مثل محقن الوقود، ومضخة الوقود، ومنظم ضغط الوقود. محقن الوقود مسؤول عن إمداد الوقود إلى غرفة الاحتراق في المحرك، حيث يختلط مع الهواء ويحترق لإنتاج الطاقة. كمية الوقود التي يتم حقنها في المحرك ستختلف بناءً على سرعة المحرك وحمولته.

يلعب مضخة الوقود دورًا مهمًا أيضًا. فهي تسحب البنزين من خزان الوقود وتقوم بتوصيله إلى محقنات الوقود. وتم تغذيتها بالطاقة بواسطة بطارية السيارة، مما يضمن استمرار تدفق الوقود إلى المحرك في جميع الأوقات. وإذا كانت مضخة الوقود معطلة، فلن يتمكن المحرك من تلقي الوقود اللازم لتشغيله. ومكون آخر مهم هو منظم ضغط الوقود. فهو يضمن وصول الوقود إلى المحرك بضغط مناسب. وهذا أمر بالغ الأهمية لأن إذا كان ضغط الوقود أقل من المتطلب، يمكن للمحرك أن يعمل بنقص الوقود (lean)، وإذا كان الضغط أعلى، فقد يؤدي ذلك إلى تلف المحرك.

ذات جودة عالية من النقاط الأخرى التي يجب أخذها في الاعتبار هو السعر نفسه لحاقن السكك المشتركة. ضروري لعمل محرك السيارة بشكل مثالي. يساعد نظام حقن البنزين الخاص بالمركبات في التأكد من أن هذه المكونات تحقق اقتصادية وقود مثالية عند عملها بشكل صحيح، مما يمكن أن يزيد من عدد الأميال التي يمكن قطعها لكل خزان بنزين. وهذا يوفر المال للسائق ويقلل من الانبعاثات الضارة التي قد تدخل إلى الغلاف الجوي. من ناحية أخرى، يمكن أن يتسبب نظام حقن بنزين رديء الجودة في العديد من المشاكل. قد تظهر بعض هذه المشكلات على شكل تشغيل غير مستقر للمحرك، أو توقفه دون تحذير، أو مقاومة التسارع عند دفع دواسة الوقود.

طرق لتحسين أداء وكفاءة الاجتماعات مع أنظمة حقن البنزين. عند ضبطها، يمكن أن تزيد من قوة الحصان (كمية القوة التي يمكن للمحرك إنتاجها) والتسارع (سرعة تسارع المركبة)، وتحسن استجابة الدواسة (كمية سرعة استجابة المحرك عندما يتم الضغط على دواسة الوقود). كما أن نظام حقن بنزين جيد يقلل أيضًا من استهلاك الوقود، مما يوفر المال على البنزين ويقلل من الانبعاثات الضارة الملوثة للبيئة.

أنظمة الحقن الحديثة مثل حقن المنافذ وحقن مباشر يمكن أن توفر مزايا أكبر. يقوم حقن مباشر بحقن الوقود مباشرة إلى غرفة الاحتراق مما يحسن كفاءة استهلاك الوقود ويخفض الانبعاثات. لهذا السبب، يمكن للسيارات المزودة بأنظمة حقن مباشر الحصول على اقتصاد أفضل في استهلاك الوقود وإنتاج انبعاثات أقل. يقوم حقن المنافذ بإرسال الوقود إلى منفذ الاستنشاق لتحسين أداء المحرك وتقليل الرواسب التي قد تتراكم داخل المحرك.

حقن المنفذ، وهو تقنية قديمة، يرش الوقود في منفذ السحب قبل دخوله إلى غرفة الاحتراق. إنه تصميم بسيط ومتين عمل بكفاءة لعقود. كما أنه، بشكل عام، أقل تكلفة من أنظمة الحقن المباشر. العيب الرئيسي لحقن المنفذ هو أنه ليس فعالًا مثل الحقن المباشر؛ وبالتالي، فإن المحركات التي تعمل بالحقن على المنفذ تستهلك المزيد من الوقود وتطلق المزيد من الانبعاثات إلى الغلاف الجوي.

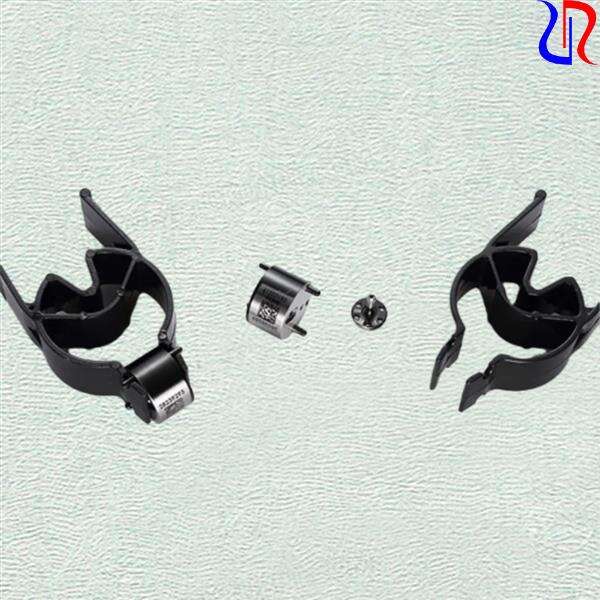

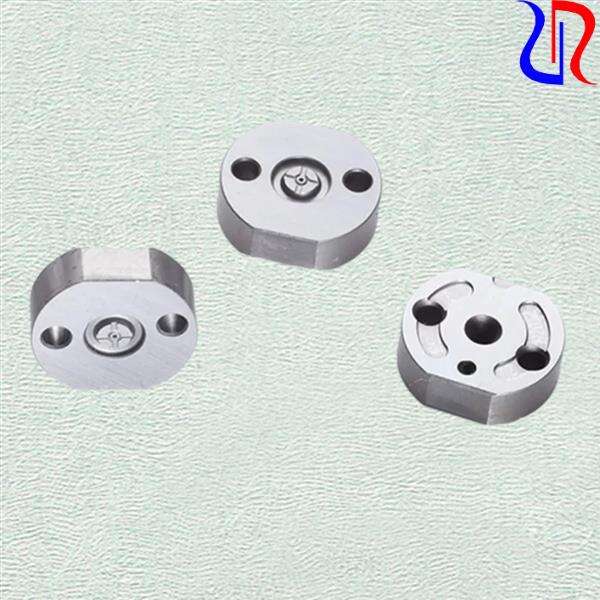

تضم شركة ديرن أكثر من ٣٠٠ مجموعة من أحدث أنظمة حقن البنزين، كما استوردت الشركة تكنولوجيا الإنتاج المتطورة على أعلى مستوى، ومعدات التصنيع والاختبار الحديثة، فضلاً عن إدخال تقنيات البحث والتطوير والتصنيع في القطاع الصناعي. ويعمل في شركة ديرن أكثر من ٣٦٠ موظفًا، بينهم ١٠ مهندسين كبار. وقد نجحت الشركة في تطوير وتصنيع رشاشات الوقود لأنواع عديدة من المركبات، وتجميعات صمام الرشاش، ومضخات الوقود، والفوهة، وغيرها.

وقد حددت شركة ديرن لنفسها هدف إنشاء مؤسسات صديقة للبيئة، وتضع دائمًا حماية البيئة في مقدمة أولوياتها في مجال أنظمة حقن البنزين وفي أبحاث التطوير. وهي أيضًا تؤمن إيمانًا راسخًا بأعمال محركات الديزل التي تتميز بانبعاثات منخفضة جدًّا، وهدوء تشغيل، وأداء عالٍ، وتلوث ضئيل جدًّا.

حصلت شركة ديرون على شهادة الأيزو 9001 وكذلك الأيزو/TS16949. وتمتلك ديرون مجموعة متطورة من أنظمة حقن البنزين عالية الجودة. وتُجري الشركة فحصًا دقيقًا لجميع الأجزاء قبل خروجها من المصنع، وذلك لأداء مهام مراقبة الجودة على أكمل وجه.

تُعد ديرون واحدة من شركات تصنيع مكونات أنظمة حقن البنزين في الصين، ولديها خبرة تزيد عن 38 عامًا في الإنتاج وإنتاج أكثر من 1000 مكوّن. وتُباع المنتجات التي نقدمها في جميع أنحاء العالم من خلال أكثر من 300 تاجر. وقد أنشأت الشركة حاليًا ثلاث شركات تابعة في الصين، وقامت بتأسيس علاقات تعاون قوية مع أكثر من 30 دولة حول العالم.

حقوق النشر © شركة قوانغتشو ديرون للآلات والمعدات الكهربائية المحدودة جميع الحقوق محفوظة - سياسة الخصوصية