There are various kinds of vehicles and machines that we come across each day that are powered by diesel engines. They include long-haul trucks that ship goods, buses that ferry people around, generators that supply electricity and construction equipment at job sites. Common-rail system is one major component of the modern diesel engines. This system is vital to the process to make sure the right amount of fuel is injected into the engine at the correct temperature to actually combust that fuel for efficiency. This article will put the basic parts of common rail systems on display, what their job is in the system, and how it all works together.

The high pressure pump is driven off the engine. It gets to very high pressure, to unexpectedly high pressure sometimes, to pump fuel into the common rail. The common rail is simply a metal pipe that serves as a reservoir for the fuel. It catches the fuel before it gets injected into the engine's cylinder by the injectors. Each injector needs to squirt fuel into the chamber at the exact right time, which is determined by signals from the engine's control unit, called ECU.

The injector's main stage then opens, and a powerful jet of fuel sprays into the cylinder through a nozzle. This atomizes the fuel into small droplets or a fine mist that combines with air and combusts. But the duration and timing of the fuel spray are critical during the fuel injection process. Getting this timing exactly right serves to ensure optimal fuel consumption, greater power and lower emissions. Common rail injectors operate under high pressure and high temperature, which requires regular maintenance of the common rail injector to function properly.

One of the outstanding facilities of common rail systems is the check and control of fuel pressure and the timing of the injection while the engine is in operation. This is achieved through the use of pressure sensors that monitor the pressure within the common rail and the fuel lines. The ECU receives this important data from these sensors. It then adjusts the pump and the injectors to ensure that the engine runs smoother and consumes less fuel.

The common rail system would fail without these pressure sensors as they function as the key to their operation. That may cause all kinds of issues, including everything from an engine that doesn’t properly combust fuel to a car that can be much worse than usual for the environment. That is why today pressure sensors play a very important role for modern diesel engines. They ensure that the engine can live longer and perform better overall because of their accuracy and reliability.

Wear and tear, dirt, or electrical problems can cause a fuel pump to fail. If this occurs, it loses its pressure and fuel flow, resulting in rough engine idling, power loss, or misfires in the engine. A qualified mechanic must be called in if there is an issue with the fuel pump's replacement, which can only be done with correct parts and tools.

Regulators play a very important role as help maintain the fuel pressure and flow in the common rail system. If a regulator fails, it can provide too high or too low pressure. This leads the engine to issues like low acceleration and black or white smoke or complete stalling of the engine. In fewer cases, simply swapping the regulator fixes the problem, but often repairs may be required to get everything working properly again.

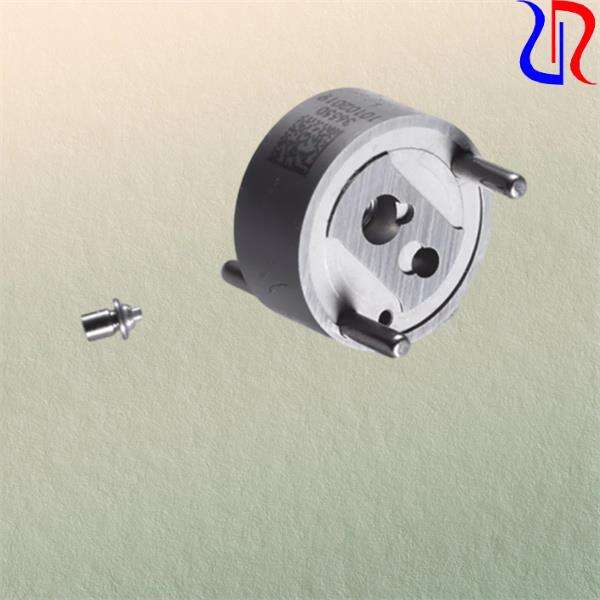

Derun has over 300 sets of the most advanced processing equipment that allows the introduction of common rail components production technology, modern manufacturing and testing equipment, and the introduction to industry of research and development and manufacturing technology. Derun has more than 360 employees comprising 10 senior engineers and 20 quality-control managers. Fuel injectors, injector valve assemblies, fuel pumps various nozzles, and more have been developed successfully.

Derun is one of the common rail components automotive diesel engine parts suppliers in China, with more than 38 years of production and over 1,000 parts. Our products are available across the world, through 300+ suppliers. It has currently set up three companies in China and established cooperating relationships with more than 30 countries in the world.

common rail components is committed to the growth of green companies as its aim, always placing green environmental protection at the top of its list when it comes to production, research and development. It is also committed to the diesel engine power business with low emissions, low noise, excellent efficiency and minimal pollution.

Derun is an organization that has been certified by ISO9001 and ISO/ common rail components quality control system. Derun utilizes a wide range of quality testing equipment and inspects each component before it leaves the factory.

Copyright © Guangzhou Derun Mechanical & Electrical Fittings Co., Ltd All Rights Reserved - Privacy Policy