One of the main components in hydraulic systems is the High quality valve assembly. Which is very crucial for the better and efficient working of the system. At Derun Mechanical, we know that an excellent valve bank assembly can be conducive to the success of any hydraulic system. In this article, we will explore the valve bank assembly itself: what it is, how it helps hydraulic systems effectively optimize performance, tips for maintenance and care, its design, and much more about why high-quality assemblies are vital.

Valve bank assembly allows to have hydraulic systems work better by regulating the flow and pressure of the working fluid inside them. This is significant because that means the systems can be making decisions quicker and more accurately thus performing at optimal levels. By means of valve bank assembly we can control the motion of hydraulic fluid with great care or with precision. This functionality is extremely vital for numerous applications. Hydraulic circuits are a requirement for the proper working of construction equipment, industrial machines, and some aerospace technologies. If the valve bank assembly fails to function properly, these machines are unable to perform their jobs effectively and in a safe manner.

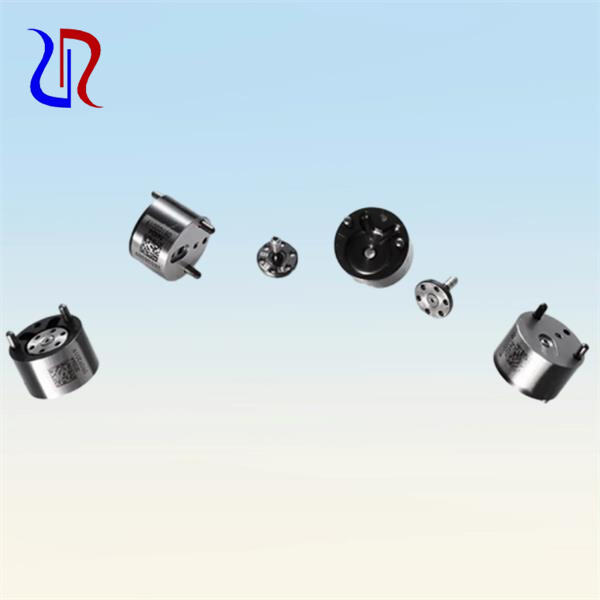

A 621C control valve contains many types of essential components, with each performing a specific function. Such components consist of solenoid valves, flow control valve relive tents and directional valves. Together they help collectively in controlling the velocity and pressure differential in hydraulic systems. Application: Solenoid valves assist in opening and closing other system valves that play a significant roll of motion. Flow control valves open and close to allow for the specific volume of fluid that needs to be used in directing the function of a task. Relief valves are critical since they save the system from over-pressure situations, which can create mayhem. And lastly, directional valves enable the desired path of flow of the fluid by directing it to its application.

A valve bank assembly is always in working condition, but they need proper maintenance. Caring for it means regular cleaning and inspection of all its components. If you find that any components are frayed or messed up, replacing them immediately is essential for stopping larger problems from arising. A big part of maintenance is the levels of hydraulic fluid. Refill the Irish whenever these levels are low, and change the fluids as recommended. Maintaining the valve bank assembly allows its performance to be maximized over a long period of time, which means that it will work better for longer.

Valve bank assemblies are built in numerous configurations, and the configuration is determined by application. While some assemblies are designed to be very specific to a particular form of hydraulic system, others can be much more generical and used in lots of different ways. Functionality of each valve bank assembly varies depending on the parts used in it, and the type of hydraulic system it is designed for. Choosing the appropriate valve bank assembly fit for a certain job will guarantee that your hydraulic system performs at optimum levels so you can achieve more than satisfactory results.

Hydraulic systems must operate safely and reliably, which makes high-quality valve bank assembly very important for control systems. In fact, a design of valve bank assembly performed inaccurately or being worse in handling gives rise to huge disaster like system crashing with weld commands and risk upon operators and equipment. This can be avoided by instrumentation valve bank assembly manufacture and looking for a reliable manufacturer such as Derun Mechanical. This means you can be sure that your control systems are running at their best.

Derun is one of the valve bank assembly for automotive components manufacturers in China that has more than more than 38 years of production and more than 1,000 components. The products we sell are sold all over the world, through 300+ dealers. It has currently set up 3 subsidiaries in China and has established strong cooperating relationships with more than 30 countries around the globe.

Derun has been certified valve bank assembly as well as ISO/TS16949. Derun's facilities include a variety of sophisticated quality testing equipment. The company strictly inspects all parts before leaving the factory to do the best job at quality control.

valve bank assembly is committed to the growth of green companies as its aim, always placing green environmental protection at the top of its list when it comes to production, research and development. It is also committed to the diesel engine power business with low emissions, low noise, excellent efficiency and minimal pollution.

valve bank assembly owns more than 300 sets of the latest processing equipment. It has developed high-end production techniques, the most advanced testing and manufacturing equipment, as well as industrial introduction of research and manufacturing technology. It owns more than360 employees comprising 10 senior engineers, and 20 quality-control executives. They have developed and tested various models of fuel injectors. inlet valve assembly, fuel pumps, nozzles etc.

Copyright © Guangzhou Derun Mechanical & Electrical Fittings Co., Ltd All Rights Reserved - Privacy Policy