A diesel engine consists of several parts including the diesel fuel injector, a small but essential piece. This small bit does significantly to the engine performance. Its function is to deliver the correct amount of fuel into the engine whenever required. It accomplishes this by opening and closing at the exact point in time, which enables it to flow fuel into the cylinder of the engine. The precise amount of fuel the valve delivers is very informative, as it ensures proper functioning of the engine and fuel efficiency. The engine can hit its best performance when all comes together!

A fuel doser injector vale has the potential to a make engine run really well. With the valve operating correctly, it puts in just the amount of fuel that the engine needs. This allows the engine to operate efficiently with lower fuel consumption overall. If an engine consumes less fuel, then this will save thousands of dollars for people who daily rely on their diesel engines for work or travel. A good valve can make a huge difference both in terms of fuel usage and engine performance. Its like giving the engine a boost, aiding it to run more efficiently — without burning more petrol!

Proper maintenance is essential to ensuring the doser injector valve for your fuel works great. You will need to regularly check that valve and clean it if it is dirty or blocked by debris, etc. For a valve to operate correctly, and to be cost-effective it needs to be clean. Additionally, check the connections to ensure they are snug. Loose connections can impact the functioning of the valve. These simple tips can help the functionality and longevity of the valve. Getting the most out of your diesel engine comes down to one thing: regular maintenance!

Maintenance is especially critical to the performance of your fuel injector for diesel engine. However, like any other valve, this one eventually runs its course and will need replacing. The incorrect amount of fuel will no longer be able to pump to the engine if this valve starts going bad. This can result in a real number of issues, for example, awful engine execution and diminished effectiveness causing more fuel utilization than required. Cleaning or replacing it is good if you notice even one sign that the valve might not work properly. It means that the engine will remain dependable and run perfectly for years to come with regular cleanings and prompt valve changes.

If you would like to save even more fuel and contribute to sustainability, then a new fuel doser injector valve is the way to go. Simply put, a modern valve is capable of controlling how much fuel actually enters the engine many times better than an older (and simpler) one could. That also means the engine can operate even more efficiently, and that's a good thing for fuel consumption. It could also reduce the harmful gases from coming diesel engine into the environment. While a new valve can improve engine performance, this upgrade also indicates a commitment to being a good steward of the Earth.

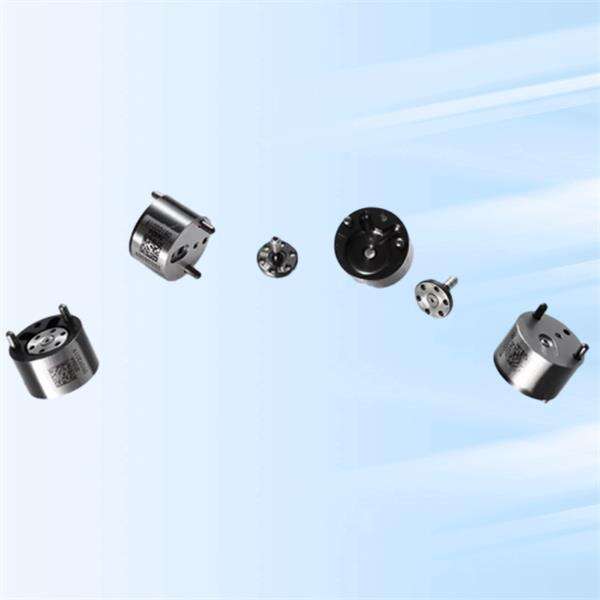

Derun is one of the fuel doser injector valve for automotive components manufacturers in China that has more than more than 38 years of production and more than 1,000 components. The products we sell are sold all over the world, through 300+ dealers. It has currently set up 3 subsidiaries in China and has established strong cooperating relationships with more than 30 countries around the globe.

Derun is an organization that has been certified by ISO9001 and fuel doser injector valve/TS16949 quality system. Derun has a range of sophisticated quality testing equipment. The company strictly inspects all parts before leaving the factory to do the best job at quality control.

Derun has set the development of green businesses as its goal, always puts green environmental protection in the first place in both research and development. It is also committed to the power industry of diesel engines with low emissions, fuel doser injector valve, high performance, and low pollution.

Derun has more than 300 sets of advanced processing equipment and has introduced the latest production technology in the world, as well as advanced testing and manufacturing equipment, as well as industry introduction of research and development and manufacturing technology. Derun employs more than 360 employees comprising 10 engineers who are senior. Injector valves, fuel injection assemblies, fuel pumps, the nozzles and many more models are being developed with fuel doser injector valve.

Copyright © Guangzhou Derun Mechanical & Electrical Fittings Co., Ltd All Rights Reserved - Privacy Policy